What conveyor belting services does MIR provide?

From simple belting replacements to entire facility process improvements with documented ROI, MIR provides conveyor belting services for all aspects of your plant’s production. Here are the conveyor belt services MIR provides for your facility.

The MIR Belting Audit™ Request

Get a line-by-line itemization of potential ROI for each improvement — at no cost to your facility.

Get startedConveyor belt ordering and delivery

When your facility needs a new conveyor belt, pulley or belting accessory, MIR’s team is always available to begin the ordering process online or over the phone. Click here to find your nearest MIR location for phone orders.

You’ll work with a dedicated sales representative fully trained in belt fabrication to order your conveyor products. And with our deep inventory from the world market of conveyor belting products, we have the ability to deliver off-the-shelf products with same-day shipping, ensuring minimal downtime for your facility.

24/7 Repair and replacement

All MIR locations are around-the-clock services centers. In the case that a belt breaks down, our technicians will be on site within hours to provide break-fix service. Safety- and fabrication-trained experts will replace or repair your belt efficiently and schedule a follow-up visit to ensure the solution met your facility’s needs. Click here to learn more about our conveyor belt repair and replacement services.

In-house custom fabrication

Conveyor belts are by no means standard — plants face unique challenges conveying food products of every size or non-food products in every shape. To meet those challenges, MIR customizes belting to your application’s specific needs.

MIR’s production facilities use best-in-class fabrication technology, including digital and diamond-tip skivers, vacuum tables and CNC machines, to customize your belts. We fabricate belts with guides, cleats, sidewalls, splicing and more to fit the application — even if the fabrication has never been done before. And because our customization is completed in-house, the lead time for a custom-fabricated belt drops from months to weeks or days.

Training seminars for facility team members

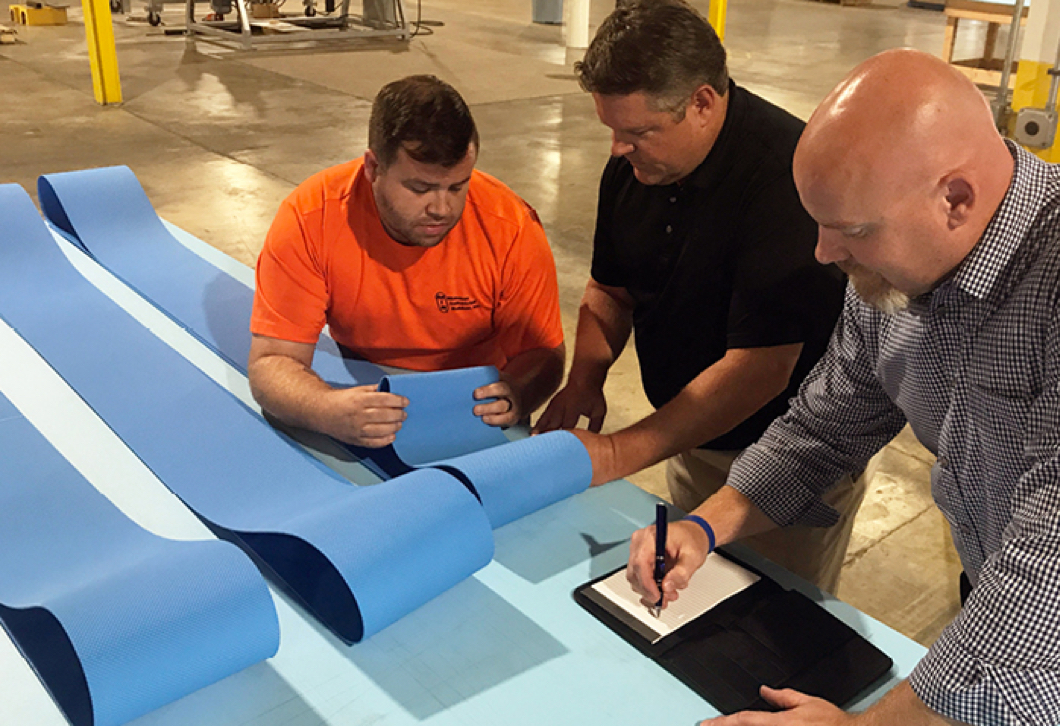

MIR’s conveyor belting experts are always on-call to address unforeseen damage and implement break-fix services. But for those few hours before a belting expert can arrive, facility team members must understand their conveyor belts and how the systems function. To aid facility managers, maintenance mangers and engineering managers, we offer conveyor belting training sessions.

Facility team members will learn from dedicated conveyor belting experts about product applications, methods for conveyor system efficiency improvement and special topics for their industry. We share our belting expertise so you can play an active role in improving your conveyor systems.

Facility process enhancement through our Continuous Improvement program

In addition to delivering custom, high quality conveyor belting and break-fix services, MIR also offers long-term process refinement through our Continuous Improvement (CI) program.

The program begins with the MIR Belting Audit™, where a belting expert goes through your facility to determine potential areas of improvement. The representative will bring a deep familiarity in conveyor belting technology and its uses across applications. At the end of the audit, you’ll receive a line-by-line itemization of every potential improvement for your facility — and its potential ROI. Takeaways from a Continuous Improvement consultation can include:

- Recommendations of improved belting materials, with priority access to the latest belting technology

- Sanitation recommendations to meet FDA, USDA, 3A, AIB, SQF standards and more

- Safety recommendations to protect worker safety

- OEM part conversions with enhanced performance specs

- Storeroom recommendations to manage inventory levels and prevent overstocking

Additionally, Continuous Improvement consultations can be a part of regularly scheduled maintenance for your facility. For example, Food Processing facilities take advantage of this service to ensure belts consistently meet strict sanitation standards. Our Continuous Improvement program can act as a supplement to your maintenance program, offering proven ROI and providing a trusted partner for facility process improvement.

A belting audit catches belting issues before they cause major breakdowns, offers solutions for pain points and provides a line-by-line itemization of potential ROI for each improvement — at no cost to your facility. Sign up for the MIR Belting Audit™.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)

Intro

Intro