Chronic belt cutting causes costly replacements

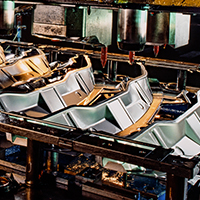

These automotive hood lines had traditionally moved face-up parts from press to press with no issue. But newly introduced part lines created a chronic problem with the sharp edges of parts facing down and cutting belts, and the severe damage caused failure on the top covers of the standard Carbox roughtop belting. This resulted in the manufacturer incurring increased replacement costs and added downtime, as the frequent cutting problem only allowed the standard belting to last four to six weeks.

MIR’s solution and facility savings

Through multiple tests, MIR’s conveyor belting experts developed a new design to solve the problem of sharp part edges consistently cutting the belts. A newly designed belt UV 210 (Part #1943740), which uses proprietary material designed exclusively for MIR, provided a cost-effective solution that led to significant savings for both the facility and the manufacturer.

After 18 months of testing, the plant saw four times greater belt lifespan with MIR’s belting solution compared to the original standard belt. The savings in the cost of the belt and the avoidance of frequent downtime resulted in total savings of approximately $68,000 over the 18-month period. Furthermore, the solution originally applied to a single parts line only, but when the plant added the MIR belting product to other similar manufacturing lines, they generated additional savings throughout the entire production facility.

Conveyor belting problems causing frequent replacements, mis-tracking or product damage are costly to your facility. Consider a belting audit with an experienced conveyor belting expert and stay ahead of conveyor belting issues. Sign up for the MIR Belting Audit™.

Case study highlights

Industry:

Automotive & MetalProblem:

Sharp edges of downward facing parts caused cutting damage and belt failure

Solution:

UV 210 (Part #1943740) uses proprietary material designed exclusively for MIR

Results:

$68,000 in savings, avoidance of frequent and costly downtime

The MIR Belting Audit™ Request

Get a line-by-line itemization of potential ROI for each improvement — at no cost to your facility.

Get started View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)