The MIR Belting Audit™ Request

Get a line-by-line itemization of potential ROI for each improvement — at no cost to your facility.

Get startedBaking & Confectionery

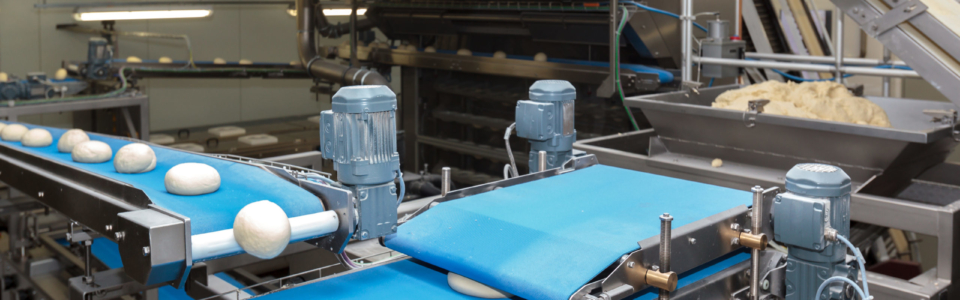

Baking & Confectionery facilities face many complicated challenges conveying ingredients, doughs, formed products and packages — often incredibly delicate — through the manufacturing process. MIR has an extensive range of belts to support all of your applications, offering Homogeneous Positive Drive Belts, High strength Plastic Modular Belts, Fabric Reinforced Conveyor Belts and more. Our cost-effective solutions and services ensure your operation performs efficiently, with hygiene as top priority.

MIR has specialty fabrication capabilities for conveyor belts manufactured in polyester, polyurethane, silicone, neoprene, Teflon® and other materials for the Baking & Confectionery Industry.

Common Applications:

- Vertical Dough Feed

- Model K Rounder

- Proofers

- Elongater

- Pan-O-Mats

- Dough Make-Up

- Sheeters

- Dividers

- Rounders

- Moulders

- Rotary Molders

- Rotary Cutters

- Vacuum Depanner

- Packaging

- Seasoning

- Scrapers

- Cooling Tunnels

- Oven In-Feed

- Oven Out-Feed

- Pan Transfer

- Dough Transfer

- Topping Machines

- Laminators

- Slicers

- Enrobers

- Flour Collectors

- Pan Stacker/ Unstacker

- Dough Chunker

- Cooler Load On/Off

- Metal Detectors

- Pressure Boards

Features Available:

- Food Safety

- Hygienic Designs

- High Temperature

- Non-Marking

- Special Covers

- Non-Fraying

- Excellent Tracking

- Spliced Endless Belts

- Antimicrobial

- High Grip

- High Release

- Easy Clean

- Cleats, Sidewalls, Scrapers and Other Modifications

- FDA, SQF, AIB & BISSC Compliant

- Metal Detectable

Fruit & Vegetable

Facilities processing fresh produce must handle products carefully, quickly and with the highest regard for sanitation. Fruit & Vegetable facilities need belts that meet FDA and FSMA guidelines to prevent contamination and protect consumer safety. To accommodate high-speed harvesting equipment, specialty belts are required.

To meet these requirements, MIR fabricates Positive Drive Conveyor belts, high strength Plastic Modular Belts, Roller Belts, custom Timing Belts and more to increase durability and product release. Our cost-effective solutions and services ensure your operations run at high speeds with minimal downtime.

Common Applications:

- Chopping/Shredding

- Harvesting Belts

- Elevator/Incline Belts

- Sorting

- Rinsing

- Dicing/Trimming/Slicing

- Dewatering

- Canning

- Sieving

- Portioning

- Blanching

- Sifting/Washing

- Roller Conveyor

- Packing

- Juicing

- Sterilizing

- Freezing Tunnel

- Labeling

- Drying

Features Available:

- Non-Stick

- Antimicrobial

- High and Low Friction Covers

- Mesh belts

- Chemical Resistant

- Cold Resistant Belts

- Excellent Release

- Cleats and Other Modifications

- Non-Fraying Edges

- Excellent Tracking

- Spliced Endless Belts

Grain Milling & Feed

The Grain Milling & Feed industry moves tons of grain and feed every day and requires belts that can handle products in a sanitary and gentle manner. MIR provides incline belts, heavy-duty belts and pulleys. We provide specialized splicing and custom cleating for the demanding applications of this industry.

Common Applications:

- Storeveyor

- Packaging Storage

- Grain Thrower Belts

- Line Shaft Drives

Features Available:

- Incline Belts

- Heavy-Duty

- Food Safety

- Modifications such as Cleats

Pet Food

Manufacturers are meeting the demand for nutritious Pet Food with high quality, FDA- and USDA-compliant wet food, dry food and specialty treat products.

MIR fabricates belts to meet the needs for various wet and dry products with finger spliceable belts, spiral technology solutions, Kevlar® reinforced thermoplastics and anti-wicking belts.

Common Applications:

- Rotary Molder

- Slicer / Dicer Equipment

- Incline to Chunker

- Incline to Palletizer

- Hopper to VFFS

- Bagger

Features Available:

- Incline Belts

- Food Safety

- Anti-Wicking

- Increased Grip

- Detection of Foreign Materials

- FDA and USDA Compliant

- Easy to Clean

- Hygienic

- Modifications such as Cleats

Snack Food

Characteristics of the Snack Food industry like complex packaging, sticky products and limited shelf life create distinctive manufacturing and processing challenges. For conveying these unique products, Snack Food plants need belts with excellent release properties and anti-wicking characteristics for products like energy bars, potato chips, gummy candies and pretzels.

MIR has an extensive range of belting solutions for Snack Food applications, with hygienic, easy-to-clean surfaces. We provide food-safe Homogeneous Positive Drive Belts, High strength Plastic Modular Belts, Fabric Reinforced Conveyor Belts and more. Our cost-effective solutions and services ensure your operation performs efficiently, with hygiene as top priority.

Common Applications:

- Dough Mixer

- Vertical Dough Feed

- Model K Rounder

- Proofers

- Elongater

- Pan-O-Mats

- Dough Make-Up

- Sheeters

- Dividers

- Rounders

- Moulders

- Rotary Molders

- Rotary Cutters

- Vacuum Depanner

- Packaging

- Seasoning

- Scrapers

- Cooling Tunnels

- Oven In-Feed

- Oven Out-Feed Pan Transfer

- Dough Transfer

- Depositor

- Topping Machines

- Laminators

- Slicers

- Enrobers

- Flour Collectors

- Pan Stacker/ Unstacker

- Dough Chunker

- Cooler Load On/Off

- Metal Detectors

- Pressure Boards

- Stacker

Features Available:

- Food Safety

- Hygienic Designs

- High Temperature

- Non-Marking

- Antimicrobial

- Special Covers

- Non-Fraying

- Excellent Tracking

- Spliced Endless Belts

- High Grip

- High Release

- Easy Clean

- Cleats, Sidewalls, Scrapers and Other Modifications

- FDA, SQF, AIB & BISSC Compliant

- Metal Detectable

- Impact & Cut Resistant

USDA & Dairy

Production facilities for USDA meat and poultry products process goods at high speeds and under stringent sanitation standards. The same goes for plants producing dairy products filling grocery stores and restaurants across the country. For USDA facilities, all equipment — especially conveyor belts — must be designed with sanitary characteristics and be able to withstand daily scrubbing and sanitizing. Conveyor belts for dairy facilities must receive 3A Council approval, meeting sanitation and contamination regulations.

MIR has an expansive range of belting solutions for your USDA & Dairy applications that comply with the strict sanitation standards and reduce food safety risks. We offer food safe Homogeneous Positive Drive Belts, High strength Plastic Modular Belts, Fabric Reinforced Conveyor Belts and more. Our cost-effective solutions and services ensure your operation performs efficiently, with hygiene as top priority.

Common Applications:

- Slicer Belts

- Dip Tanks

- Stunning

- Skinning

- Scalding/Cleaning

- Bulk Product Transfers

- Trim Lines

- Frozen Block Inclines

- Shredding

- Cubing

- Receiving

- Defeathering

- Evisceration

- Byproduct Recovery

- Offal

- Chilling

- Weighing/Batching/Grading

- Patty Former

- Milk Treatment

- Cooling/Brining

- Cheese Production

- Ripening

- Molding

- Outfeed Conveyor

- Further Processing

- Packaging/Logistics

Features Available:

- Food Safety

- Hygienic Designs

- High Temperature

- Non-Marking

- Antimicrobial

- Special Covers

- Non-Fraying

- Excellent Tracking

- Spliced Endless Belts

- High Grip

- High Release

- Easy Clean

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)

Baking & Confectionery

Baking & Confectionery