What are Homogeneous Positive Drive conveyor belts?

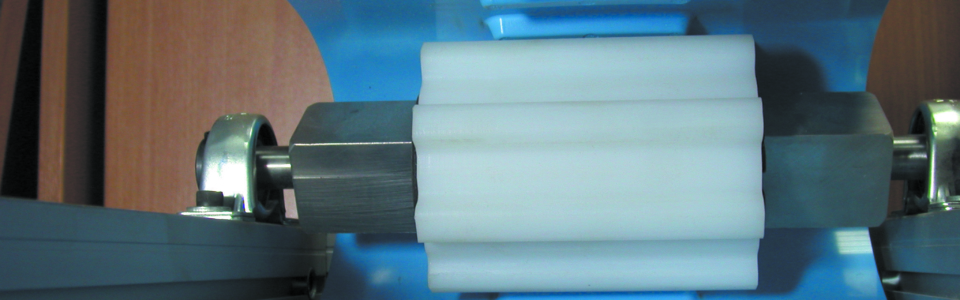

Homogeneous Positive Drive conveyor belts are extruded with thermoplastic urethane in various thicknesses. They are extruded with a smooth cover surface or with cover impressions. These belts can be custom engineered with a variety of add-ons, such as cleats and sidewalls or machined modifications. These belts are positively driven by an extruded bar on the drive side of the belt which then interfaces with a matching pulley. We offer two extruded bar designs: Dual Drive and Super Drive. Super Drive ensures positive tracking without side-to-side movement.

The homogeneous structure of the belt makes it an excellent choice for applications where sanitation and hygiene are essential to production uptime.

Modular belts are another positive drive solution. To learn more about modular positive drive belts, click here.

The MIR Belting Audit™ Request

Get a line-by-line itemization of potential ROI for each improvement — at no cost to your facility.

Get startedAdvantages of Homogeneous Positive Drive belts

Homogeneous Positive Drive belts offer many advantages for conveying applications where line sanitation is crucial. The holistic structure of these belts means reduced costs in water use, less downtime for cleaning, extended belt life and an overall increase in production line output.

- Simplified Sanitation

- Less Maintenance – a 75% reduction in cleaning time

- Durable

- Abrasion-Resistant

- Food Safety

- FDA, USDA and 3A Dairy Compliant

- Reduced Water Consumption

- Corrosion-Resistant

- Less Chemicals

- Reduced Downtime

- Extended Belt Life

- No Bacteria Traps

- Scraper Friendly

- No Edge Fraying

- No Tracking Issues

- Oil Resistant

- Various Cover Features Available

- Customizations (see below)

Customization options

Positive Drive belting can be customized to fit the exact need of your conveying application — that’s where MIR’s customization capabilities come in. With our high-frequency welding units and experienced belting experts, you’ll get a Positive Drive belt that improved handling effectiveness, eliminates product waste and improves overall reliability. And because all our customization occurs in-house, we can react quickly on lead times and make adjustments ourselves, ensuring a best-fit product in a quick turnaround. Our Positive Drive customization options include:

- Straight or Curved Sidewalls

- Straight or Scooped Flights

- Texture

- Perforation

- V-Guides

- Endless Splicing

- Mechanical or Plastic Lacing

- Metal Detectable Options

Considerations for Homogeneous Positive Drive

Users should be aware that Positive Drive belts are limited on the heat they can withstand — they will start to show wear starting at 170 degrees Fahrenheit. For conveyor applications involving high heat, consider our other conveyor belting options, or speak with a belting expert to determine the best-fit belt for your application.

Homogeneous Positive Drive belting brands

MIR provides customers with Positive Drive belts from the following brands:

- Chiorino HP Compact Drive

- Cog-Veyor

- Gates Mectrol

- Magnathane

- Volta SuperDrive

- Volta Dual Drive

From these top-notch brands, we offer 61 different Positive Drive style belts, with limitless customization configurations. Reach out to a conveyor belting expert to discuss how you can improve your plant’s sanitation, efficiency and maintenance with highly customized Positive Drive conveyor belts.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)

Intro

Intro