Capping Belts

Capping Belts Corrugated Box | Easy Install Knife Exit Timing Belts

Corrugated Box | Easy Install Knife Exit Timing Belts Deboning / Soft Separator Belts

Deboning / Soft Separator Belts Depanner Belts

Depanner Belts Dewatering Belts

Dewatering Belts High and Low Temperature Belts

High and Low Temperature Belts Pin-Lok Belts

Pin-Lok Belts Pocket Vacuum Belts for Box Forming

Pocket Vacuum Belts for Box Forming Puller Belts

Puller Belts Sausage Belts

Sausage Belts Seal Checker Belts

Seal Checker Belts Side Seal Belts

Side Seal Belts Tube Winder Belts

Tube Winder Belts Unwind Belts

Unwind Belts VFFS Belts

VFFS Belts

Capping Belts

MIR supplies custom high friction and cushioning style capper belts for all types of bottling and container closing applications. We offer replacement belts for top-quality capping machines used to secure caps of varying material types to bottles and containers made of Glass, PET, PVC, PP, LDPE and HPDE. Our Belts are used to guide the container to apply torque and twisting motion to securely lock the cap in place.

With unlimited cover possibilities and a wide range of substrate belt options, we offer replacement belts for most OEMs.

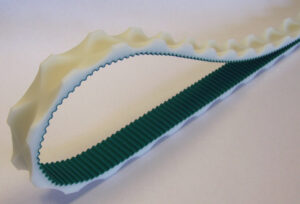

Corrugated Box | Easy Install Knife Exit Timing Belts

MIR provides Easy Install Knife Exit Timing Belts for the corrugated box industry that reduces your maintenance and downtime. Entire sets can be changed within an hour! Our replacement belts operate like the OEM, with no change in performance.

MIR provides Easy Install Knife Exit Timing Belts for the corrugated box industry that reduces your maintenance and downtime. Entire sets can be changed within an hour! Our replacement belts operate like the OEM, with no change in performance.

Common Features:

- Change a Single Belt in Minutes

- Premium, Non-Marking

- High-Temperature Compound

- Non-Vacuum Option Available

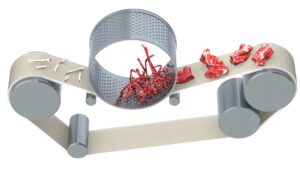

Deboning / Soft Separator Belts

MIR offers belts made with FDA material designed in rubber and urethane to gently separate and squeeze soft and solid components from meat, poultry and other USDA applications. The long-life performance of our belts helps preserve and maximize output.

MIR offers belts made with FDA material designed in rubber and urethane to gently separate and squeeze soft and solid components from meat, poultry and other USDA applications. The long-life performance of our belts helps preserve and maximize output.

Additionally, these belts are used in fruit & vegetable* processing to separate seeds and stems from the plant as well as de-packaging cartoned food products such as meat and yogurt.

Common Features:

- Wear-Resistant Endless Woven Belts

- Endless Extruded Belt Options

- Non-Cracking Covers

- Different Profile Impressions

- Easy to Clean Surfaces

- Rubber and Urethane Available

Depanner Belts

Depanner belts are used for breads and baked goods to transport and dislodge bread from pans quickly. MIR utilizes advanced technology and materials to improve depanning baked goods and increase your throughput. We provide sizes to fit all depanner equipment.

Depanner belts are used for breads and baked goods to transport and dislodge bread from pans quickly. MIR utilizes advanced technology and materials to improve depanning baked goods and increase your throughput. We provide sizes to fit all depanner equipment.

Common Features:

- Custom and Standard Alternating Row Hole Patterns

- Metal Detectable Cups and Retainers are Available

- Sanitary Homogeneous Endless Splicing

Dewatering Belts

MIR offers both mesh and modular belt designs for use in dewatering and drying applications commonly found in fruit and vegetable processing applications. These belts provide a safe way to wash products delivered from farms, while also separating contaminants such as stones for downline processing. MIR can suggest the right belt solution to maximize hygiene and production throughput for your product and wash environment.

MIR offers both mesh and modular belt designs for use in dewatering and drying applications commonly found in fruit and vegetable processing applications. These belts provide a safe way to wash products delivered from farms, while also separating contaminants such as stones for downline processing. MIR can suggest the right belt solution to maximize hygiene and production throughput for your product and wash environment.

In addition, MIR provides specialty fabrications to meet your application needs.

High and Low Temperature Belts

MIR carries belts suitable for your high and low-temperature applications including food applications such as oven exits, press-baking, cooling, cryogenic freezing, as well as tire applications.

MIR carries belts suitable for your high and low-temperature applications including food applications such as oven exits, press-baking, cooling, cryogenic freezing, as well as tire applications.

We offer PTFE (silicone coated) belts that are good for both high and low-temperature applications, as well as Silam belts used for high-temperature only.

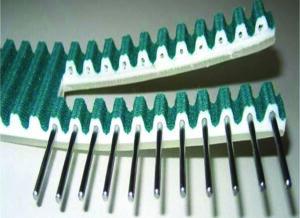

Pin-Lok Belts

Pin-Lok Timing Belts are an easy-to-install, downtime-reducing solution compared to endless belts. Pin-Lok is a timing belt splicing technology that is so simple to install that they can be safely installed in seconds without needing field welders.

Pin-Lok Timing Belts are an easy-to-install, downtime-reducing solution compared to endless belts. Pin-Lok is a timing belt splicing technology that is so simple to install that they can be safely installed in seconds without needing field welders.

These quick changes lead to increased uptime and profitability.

Common Applications:

- Log Saw Pusher

- Flight Bar Belt

- Choke Belt

- Trim-X Belt

- Case Packer

- Thread-Up Belt

Special Fabrications:

- Cleats

- Special Profiles

- V-Guides

- Covers / Backings

- Engineered Locking Pin

- Custom Grinding for Positive Tracking

Pocket Vacuum Belts for Box Forming

MIR has “pocket” vacuum replacement belts for box forming and packaging in-stock and ready to ship. Our belt features an upgraded surface compound that increases belt life.

MIR has “pocket” vacuum replacement belts for box forming and packaging in-stock and ready to ship. Our belt features an upgraded surface compound that increases belt life.

Our Pocket Vacuum replacement belts operate like the OEM, with no change in performance.

MIR #2006973:

- Replacement Belts are In-Stock and Ready to Ship

- Competitive Pricing

- Upgraded Surface Compound for Wear

Puller Belts

MIR provides a range of high-performance, high friction elastomers – rubber and urethane, to assist in the pull-through of products in applications like PVC tubing, pipe extrusion, rubber extrusion and wire stripping. Our belts are coated seamlessly, ensuring the thickness and flatness of the material are consistent throughout.

MIR provides a range of high-performance, high friction elastomers – rubber and urethane, to assist in the pull-through of products in applications like PVC tubing, pipe extrusion, rubber extrusion and wire stripping. Our belts are coated seamlessly, ensuring the thickness and flatness of the material are consistent throughout.

Covers Added to Substrates Can Include:

- Banded Belts

- Multi-Vee Belts

- Timing Belts

- Flat Belts

Additionally, in some cases, the cover requires customization to hold the product conveyed in the right position. Here we can add grooves or slots.

Common Features:

- Wear Resistance

- High Friction Top Cover

- Customized Cover Surface Finish

- Oil and Grease Resistance

- Good Chemical Resistance

- Specialty Fabrications Including Grooves and Slots

Sausage Belts

MIR offers replacement belts for major OEM sausage twisting and cutting equipment. We offer homogeneous molded belts with profiled surfaces. Our sausage belts are made with FDA molded material on various substrates that can be machined with desired surfaces to securely transport products.

MIR offers replacement belts for major OEM sausage twisting and cutting equipment. We offer homogeneous molded belts with profiled surfaces. Our sausage belts are made with FDA molded material on various substrates that can be machined with desired surfaces to securely transport products.

Seal Checker Belts

MIR’s crosslink polyester screen belt design allows the exhausted air to escape and positively identify a product for reject prior to bulk packaging. This process uses compression to check the seal closure to reject unproperly sealed products in the snack food industry.

MIR’s crosslink polyester screen belt design allows the exhausted air to escape and positively identify a product for reject prior to bulk packaging. This process uses compression to check the seal closure to reject unproperly sealed products in the snack food industry.

MIR #1913291:

- In-Stock for Same-Day Shipping

- Fabrications – Customized Per Your Specifications

- OEM Construction Available In Stock

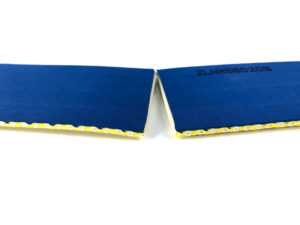

Side Seal Belts

MIR provides upgraded PTFE side seal wrapper belting materials with a proven track record to extend operational life. Increase production and machine uptime with MIR side seal wrapper belts. We offer same-day shipping on certain sizes.

MIR provides upgraded PTFE side seal wrapper belting materials with a proven track record to extend operational life. Increase production and machine uptime with MIR side seal wrapper belts. We offer same-day shipping on certain sizes.

Common Features:

- Higher Quality PTFE, Resulting in Consistent Package Sealing

- Variety of Edge Guides Available to Fit your Application

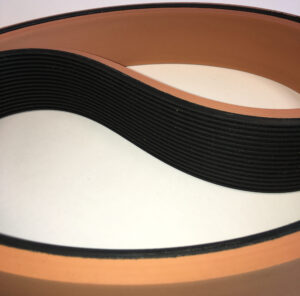

Tube Winder Belts

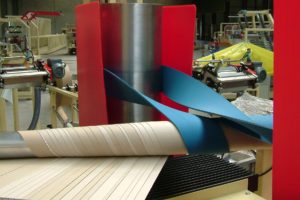

Tube winder (also known as core winder) belts are primarily used in hygiene and paper. These belts are manufactured with special splicing techniques or woven endless technology.

Tube winder (also known as core winder) belts are primarily used in hygiene and paper. These belts are manufactured with special splicing techniques or woven endless technology.

Increase operational performance and reliability while minimizing your PM cycle and maintenance with MIR’s Tube Winder Belts.

MIR #1983363:

- 2- 3 Times Performance Value

- Wear Resistant Compound

- Cast Seamless / No Splice

- Size Flexibility

- Sealed Edge Minimizing Wear and Exposure

- High Flex Cord Reinforcement

Unwind Belts

MIR #1961591 replaces flat nylon core belting – requiring minimal downtime for installation with proven reliability and performance. With its spiral screen design, welding the belt endless is not required and there will be no mechanical lace.

MIR #1961591 replaces flat nylon core belting – requiring minimal downtime for installation with proven reliability and performance. With its spiral screen design, welding the belt endless is not required and there will be no mechanical lace.

- Abrasion Resistant Cover

- Eliminates Belt Welding

- Easily Repairable

- Simple Pin Assembly

VFFS Belts

In order to assure high-speed fill, seal packaging efficiency and line uptime, food manufacturers are challenged to find the right belt cover material. MIR offers a wide range of rubber, silicone, and urethane cover options to ensure proper throughput on Vertical Form Fill and Seal machines. We offer customized fabrications including holes and slots for vacuum draw.

In order to assure high-speed fill, seal packaging efficiency and line uptime, food manufacturers are challenged to find the right belt cover material. MIR offers a wide range of rubber, silicone, and urethane cover options to ensure proper throughput on Vertical Form Fill and Seal machines. We offer customized fabrications including holes and slots for vacuum draw.

MIR’s VFFS belts are manufactured to multiple OEM specifications and are designed to increase reliability and throughput.

- MIR can manufacture custom sizes and compounds for special applications or unique films

- MIR stocks both the Track-Style and Mono-Rail Style belts – ready for shipment for specific OEM equipment

- Quick shipping on many OEM replacement belts

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)