Celebrating Global Recycling Day with MIR Belting:

Sustainable Solutions for the Recycling Industry

As the world comes together to celebrate Global Recycling Day on March 18th, MIR Belting proudly stands as a trusted partner to recycling operations, offering a comprehensive range of specialized belts tailored to meet the unique demands of the recycling industry.

The continued expansion of recycling programs, both in companies and municipalities underscores the urgent need for reliable, high-efficiency, and sustainable solutions. Recycling facilities face increasing pressure to operate faster and more reliably while sorting a wide variety of materials and upholding safety, reliability, and environmental consistency.

At MIR Belting, we understand the complexities at every stage of the recycling process, from pre-sorting and mixed-waste lines to eddy current and metal sorter systems. Our conveyor belting solutions are engineered to withstand the toughest conditions, offering resistance to abrasion, cuts, chemicals, and oils commonly found in recyclable materials. Additionally, for areas where combustible dust or materials are present, our fire-resistant belts provide essential layers of safety.

Recommended Conveying Belts for the Recycling Industry

- Heavy Black Belts: : Built to endure the most demanding recycling environments, Heavy Black Belts deliver exceptional durability and performance. Engineered to handle heavy loads and sharp, rugged materials, these belts offer superior strength and abrasion resistance—helping reduce maintenance needs, minimize downtime, and support smooth, efficient recycling operations.

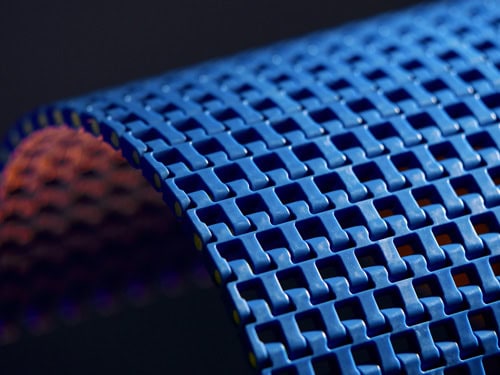

- Eddy Current Belts: Tailored specifically for eddy current and non-ferrous metal sorting, these belts enhance non-ferrous metal separation, and increase recycling efficiency and throughput. Their durable design minimizes wear and operational interruptions, ensuring smoother, more reliable processing. Eddy Current Belts are essential for advanced recycling operations seeking higher efficiency and productivity.

- Flexam EX: Flexam EX offers outstanding chemical resistance for harsh recycling environments where oils, chemicals, and corrosive materials are commonly encountered. Its robust construction reduces downtime and supports consistent operational performance.

- Nonex EM:Designed for exceptional wear resistance, Nonex EM excels in applications involving abrasive materials commonly found in recycling processes. Its long service life helps reduce belt changeouts and operating costs, supporting uninterrupted facility performance.

- Ropanyl EM: With excellent mechanical strength, Ropanyl EM ensures smooth material handling and consistent flow across recycling processes. Its reliable performance helps minimize downtime and enhance overall productivity.

Dedicated Support for Sustainable Operations

In addition to our commitment to sustainability, we pride ourselves on providing a customer-centric approach. Our team is available 24/7 to deliver expert guidance, on-site support, and solutions tailored to each facility’s unique needs. With MIR Belting, you can trust that your recycling operations are supported by durable products, industry expertise, and a service model built around reliability.

As we commemorate Global Recycling Day, MIR Belting remains dedicated to helping recycling facilities improve efficiency, safety, and environmental stewardship. Through responsible practices, reliable products, and 24/7 support, we continue to deliver on our promise of Belting Solved. Together, we can protect resources, support progress, and build a cleaner, more sustainable future for generations to come.

Happy Global Recycling Day from MIR Belting!

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)