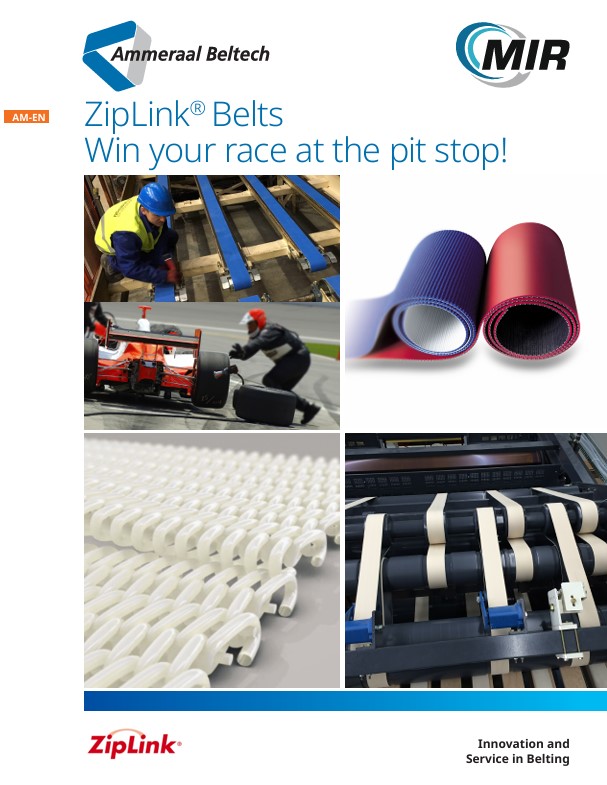

When production stops, costs rise fast. Introducing ZipLink® belts now available at MIR. This innovation belting solution makes installation and change-outs faster, easier and more reliable. This installation video series shows your team how to install and track a belt step by step-using only standard tools. No presses, No contractors, no wasted hours.

Introduction

Installation

Splice

Common Belt Issues and How ZipLink® Solves Them

Problem 1: Frequent Belt Failures

Abrasive sanding in wood processing and high heat drying in gypsum cause traditional belts to wear out quickly or fail.

Solution:

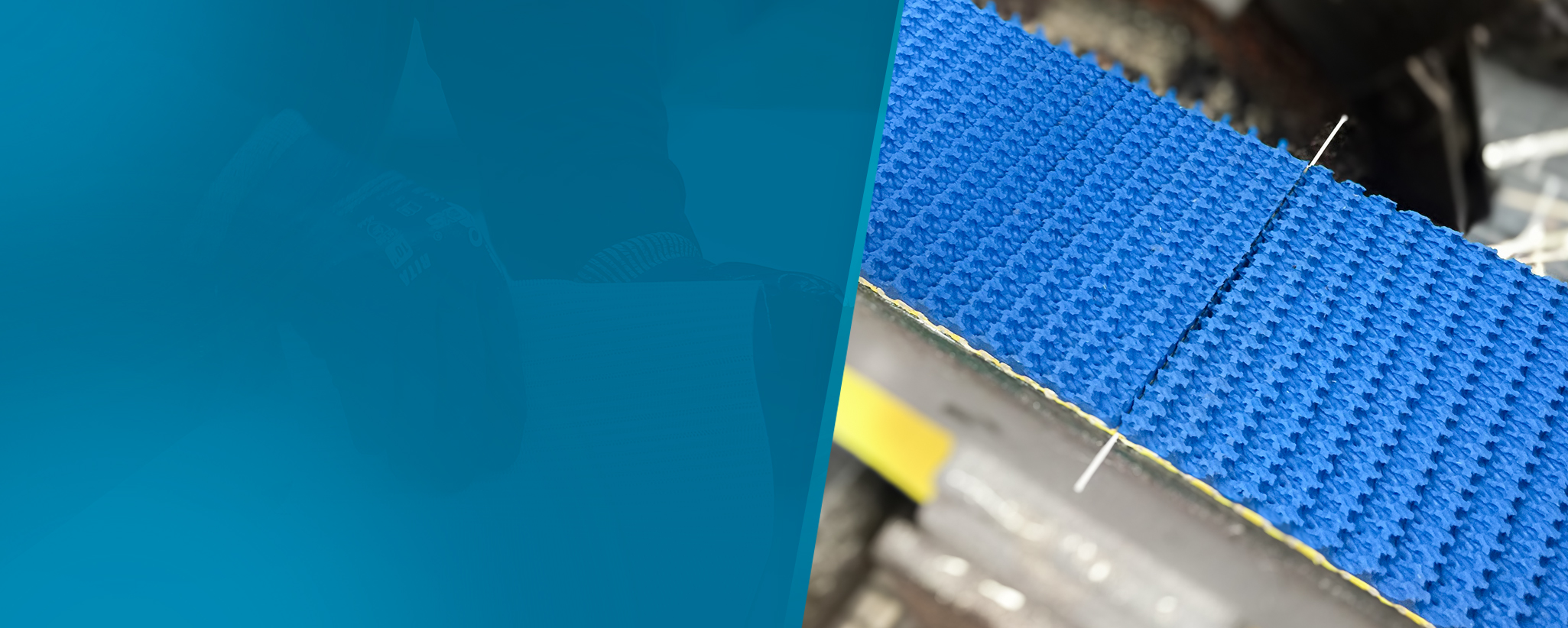

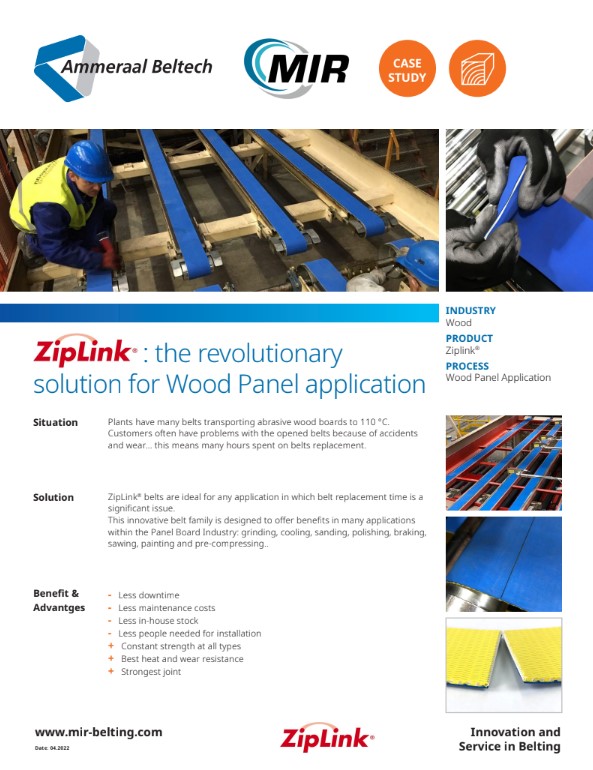

ZipLink® belts use reinforced rubber compounds like XNBR, NBR, and silicone to create a continuous, splice-less design with an integrated spiral connection that delivers consistent strength and durability, even in the toughest conditions. Read the full case study here.

Problem 2: Inconsistent Belt Tracking and Misalignment

Misaligned belts cause jams, damage products, and increase uneven wear.

Solution:

ZipLink’s® stable construction ensures uniform tension and consistent tracking, minimizing realignment needs and maintaining smooth, uninterrupted conveyor flow. Read the full case study here.

Key Benefits of ZipLink®

- Install with No Special Tools: You do not need specialized equipment, presses, or outside help. Maintenance teams can handle installation themselves, which means less waiting and faster turnaround.

- Reduce downtime and maintenance costs Installation is simple and fast, your team spends less time on repairs and your equipment runs longer with fewer interruptions.

- Increases production time and throughput Every minute saved during installation or adjustment is more time your line is producing.

- Eliminates weak joints With no weak splice area, Ziplink’s seamless construction prevents sudden belt failures.

- Resists wear for longer service life The rubber compounds and stable construction hold up under tough environments like heat, abrasion, and constant use, which means fewer replacements over time.

Why MIR?

At MIR, we don’t just supply belts—we solve belting challenges. Our Belting Solved approach delivers always-on service, custom-engineered solutions, and trusted support to keep your operations running 24/7. With 25 U.S. locations and a team that’s always ready, MIR provides the reliability, speed, and partnership your operation demands.

Let’s solve your challenges together.

For more information, reach out to customerservice@mir-belting.com or call 877-MIR-BELT

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)