In today’s food industry, facilities are under constant pressure to maximize throughput and minimize downtime while maintaining food safety standards. Conveyor belts play a critical role in this balance, yet traditional belts often create challenges that slow production and increase risks.

Ammeraal Beltech developed the Soliflex line of conveyor belts to solve these challenges. Manufactured as fully extruded polyurethane, Soliflex belts are engineered for ultimate hygiene, easy cleaning, and long lasting performance. Now available through MIR, Soliflex represents a smarter way to keep your line moving safely and reliably.

Key Benefits of Soliflex

Soliflex delivers a powerful combination of performance and hygiene features that set it apart for today’s most demanding food applications.

- One piece hygienic design No fraying, no loose fibers, no hidden crevices. Just a solid, food safe construction that reduces contamination risks.

- Easy and fast cleaning This design ensures fast, easy sanitation. The seamless surface cuts water and detergent use, while in-place and in-motion cleaning capabilities minimize downtime and conserve resources.

- Reliable tracking and smooth operation Positive drive technology, such as Soliflex PRO lugs, keeps belts aligned, minimizes realignment needs, and prevents costly stoppages.

- Durable and long lasting Engineered to withstand demanding production environments, Soliflex belts reduce unplanned downtime and extend service life.

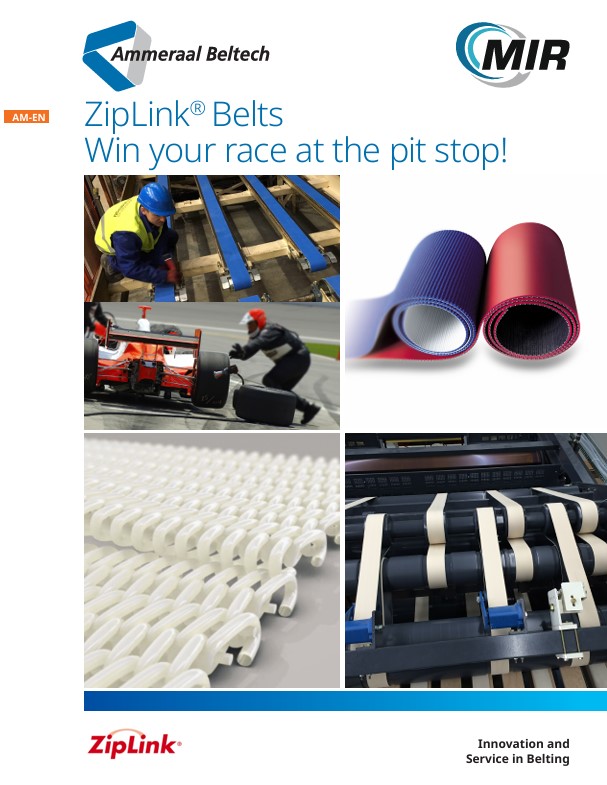

- Versatile range With multiple configurations including PRO, PRO Mini, Center Bar, Full Bar, and Full Bar Mini, there is a solution for nearly every food processing application.

- Food industry compliant Meets international food grade standards (FDA and EC 1935/2004) and supports ISO 22000 requirements for ultimate food safety.

The Soliflex Range

To fit a wide variety of applications, Soliflex is available in multiple configurations:

- Soliflex PRO – The most hygienic and advanced tracking design, with unique lug technology that engages directly with pulley teeth.

- Soliflex PRO Mini – Designed for small pulley diameters, perfect for tight transfer points and space limited conveyors.

- Soliflex Center Bar (CB) – Features smooth, wide lugs that deliver excellent tracking and are easy to clean, even in hard to reach corners.

- Soliflex Full Bar (FB) – A full width drive lug design that provides reliable performance and a hygienic alternative to plastic modular belts.

- Soliflex Full Bar Mini (FB Mini) – A compact version designed for small pulleys, ideal for transition conveyors.

Why MIR

At MIR, we do more than supply belts. Our Belting Solved approach combines technical expertise, 24/7 support, and decades of industry knowledge to keep your operations running. With 25 U.S. locations and a team that is always ready, MIR delivers the reliability, speed, and partnership your business needs.

Ready to upgrade your operations with Soliflex?

For more information, contact customerservice@mir-belting.com or call 877 MIR BELT.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)