Celebrating National Pizza Day with MIR Belting:

Bringing Your Favorite Slice to the Table

On this National Pizza Day, February 12th, we at MIR Belting extend our warmest wishes to pizza aficionados everywhere. Beyond just a celebration of this beloved dish, today marks an opportunity to highlight the unseen heroes behind your favorite slices: the conveyor belts and processing equipment that ensure your pizza is perfectly prepared, from dough to topping.

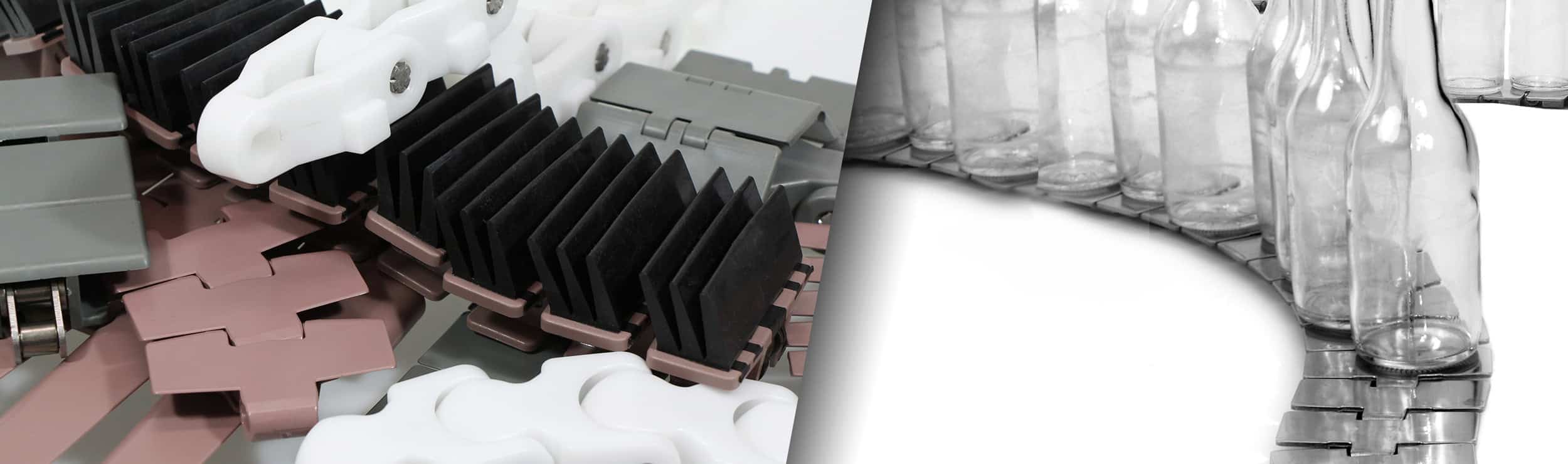

MIR Belting offers a variety of conveyor belts specifically designed for the pizza industry, ensuring efficiency, hygiene, and quality in every step of pizza production. Among these, Flex ASB, M-TTB and our specialized “Cheese Belt” (MIR-2015984) available in both standard and Metal Detectable versions.

The Flex ASB belt stands out for its exceptional performance in spiral applications. This strong, cleanable, and multi-purpose 1-inch pitch side flexing belt boasts a unique patented design that ensures reliability and strength.

With features like an improved hygienic design of the hinges, increased lateral stability requiring fewer support strips, and availability in various radii for oversized drums, the Flex ASB belt exemplifies the advanced technology that supports the pizza-making process. Its curved surface version even offers class-leading radius pull, highlighting its versatility and efficiency.

Designed with precision and efficiency in mind, the M-TTB belt is a cornerstone in the seamless operation of pizza production lines. Its durable construction and innovative design ensure the gentle handling of pizza dough as it transitions through the various stages of preparation, from kneading and rolling to baking and cooling. The M-TTB belt’s superior performance in high-temperature environments, combined with its resistance to oil and grease, makes it an indispensable tool for pizza manufacturers seeking to deliver consistently high-quality products. Its reliability and easy maintenance also contribute to a streamlined production process, reducing downtime and enhancing overall productivity.

Uni Flex ASB band

Uni M-TTB

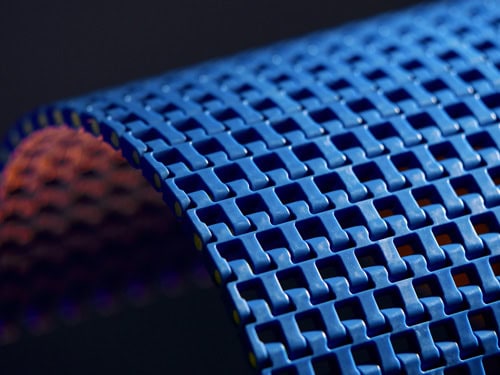

A standout in our collection is the “Cheese Belt” stands out as a marvel of ingenuity. It’s crafted from the highest quality metal-detectable premium urethane, which boasts industry-leading detector sensitivity. This is crucial for maintaining the safety and quality of your pizza. The belt’s design includes Kevlar-cord reinforcement for added strength and durability, ensuring that it can handle the rigors of pizza production without compromising on hygiene or efficiency. It is available in both standard (MIR #2036925) and metal-detectable (MIR #2015984) versions, catering to a wide range of production needs.

Its reversible design, featuring a smooth topside and a negative-pyramid backside, allows for versatile use across different stages of pizza production, from elevating ingredients to moving the finished product.

Moreover, for ingredient preparation, our belts play a crucial role, ensuring that toppings are perfectly sized for uniform cooking and distribution. In dough molding applications, our belts provide the precision and gentle handling necessary to maintain dough integrity and texture.

As we celebrate National Pizza Day, let’s remember the role of technology and innovation in bringing our favorite dishes closer to home. At MIR Belting, we’re proud to be a part of this process, ensuring that from the first bite to the last, your pizza is nothing short of perfection. Happy National Pizza Day from all of us at MIR – here’s to many more slices of joy, delivered fresh and delicious, straight to your table.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)