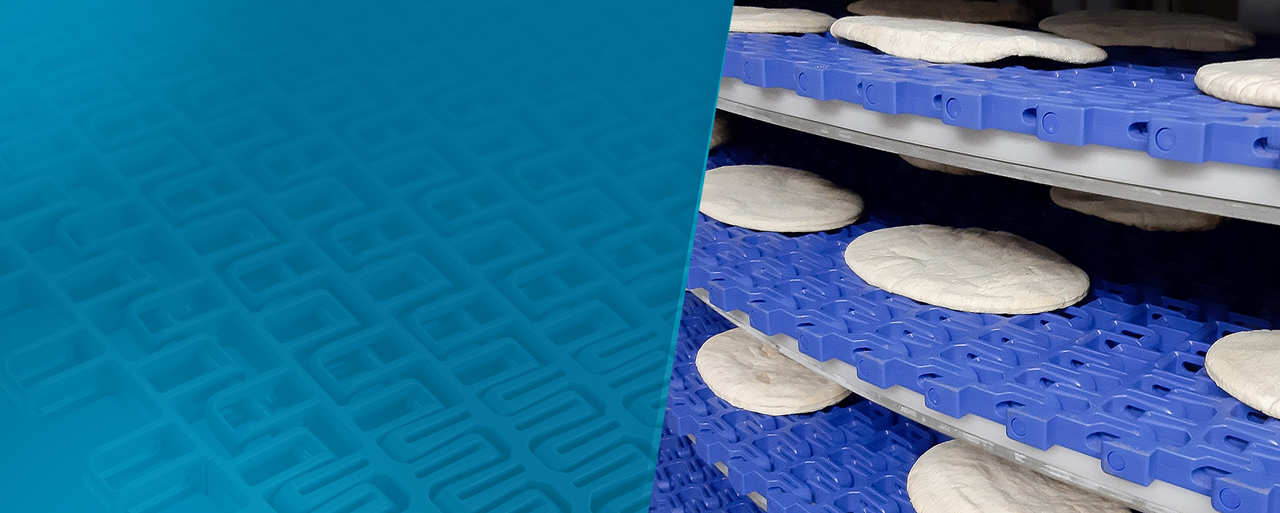

MODULAR FOR TORTILLA, FLAT BREAD & PIZZA

Hygienic. Low Maintenance.

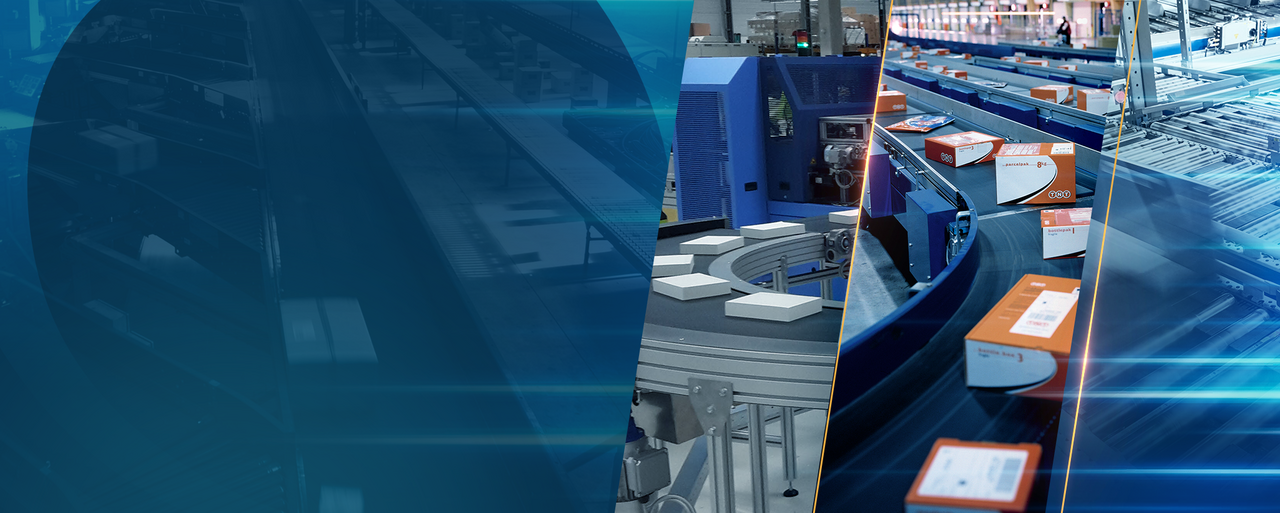

MIR has modular solutions for your tortilla, flat bread or pizza production. Recommended products and features vary per application. Our plastic modular belts are used in masa/dough handling, entering/exiting oven, bridge to cooling, multi-tiered cooling, counter-stacker and packaging.

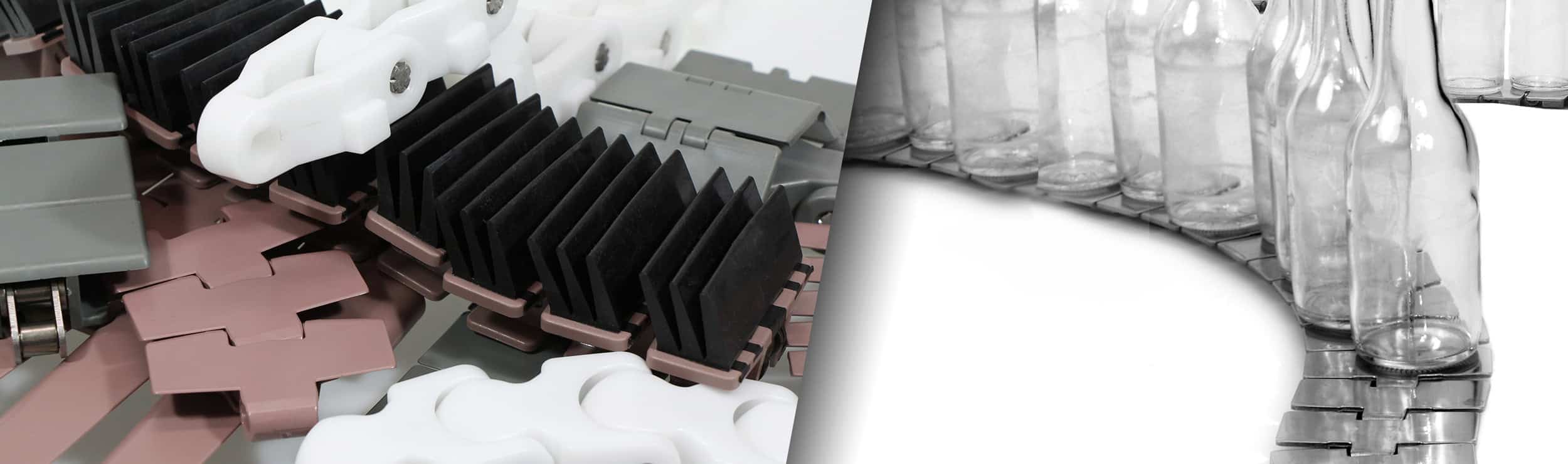

Features Available:

- Open Modules have Minimal Product Contact

- Non-Stick

- High-Temp

- Quick Cooling

- No Sweat

- Crumbs can Fall Through

- Product Stability from Sprocket Engagement

- Hygienic and Easy Clean

- Vacuum Belts

- Excellent Sprocket Engagement

- No Lane Migration

- Easily Repaired

- Rubber Top available

- Non-Dusting Plastic Modules

Click Here for full details.

Contact your MIR Continuous Improvement Specialist for specific application questions and to receive a quotation.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)